Hubs/Couplers

Product Heading

Product Heading

Hubs and couplers are essential components in precision machining and industrial applications, playing crucial roles in power transmission and shaft connection. Let’s explore these components in detail:

Hubs

Hubs are crucial connecting components that join shafts and transmit power between different parts of machinery, ensuring smooth and efficient operation in various industrial applications.

Types of Hubs

- Clamp-style Hubs: These hubs use a clamping mechanism to secure the shaft, providing a strong and reliable connection.

- Set Screw Hubs: Featuring set screws that tighten against the shaft, these hubs are simple and cost-effective.

- Keyway Hubs: These incorporate a keyway to prevent rotation between the hub and shaft, offering increased torque transmission.

Benefits of Hubs

- Secure Connection: Hubs provide a strong and stable connection between shafts and other components.

- Efficient Power Transfer: They enable smooth and efficient transfer of power between different parts of machinery.

- Versatility: Hubs can be used in various applications and industries, from manufacturing to robotics.

- Easy Maintenance: Many hub designs allow for easy disassembly and maintenance of machinery.

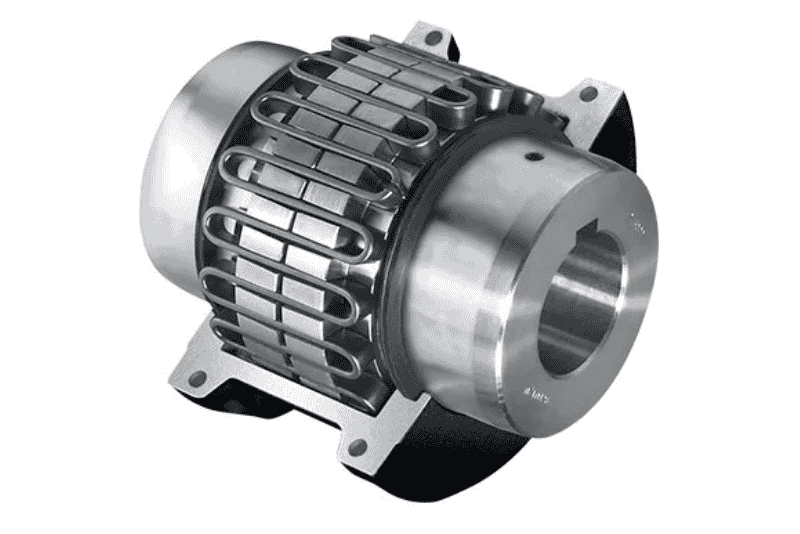

Couplers

Couplers provide strong and secure connections between rotating shafts in various applications, including power transmission systems, machinery, and robotics.

Types of Couplers

- Rigid Couplings: These connect shafts with no relative motion, maximizing torque transmission.

- Flexible Couplings: They accommodate minor misalignments and absorb shock and vibration.

- Bellows Couplings: Ideal for highly dynamic servo axes, offering zero backlash and high torsional stiffness.

- Elastomer Couplings: These provide vibration damping and are suitable for various applications.

Benefits of Couplers

- Misalignment Compensation: Couplers can accommodate angular, parallel, and axial misalignment between shafts.

- Vibration Dampening: Many couplers absorb shock and vibration, protecting machinery from wear and tear.

- Increased Flexibility: Couplers allow for easy disconnection and reconfiguration of machinery setups.

- Precision: High-quality couplers ensure accurate power transmission, crucial for precision applications.

How Hubs and Couplers Work Together

Hubs and couplers often work in tandem to create efficient and reliable power transmission systems:

- Connection Interface: Hubs typically attach to the ends of shafts, while couplers join these hub-equipped shafts together.

- Power Transfer: The hub secures the shaft, and the coupler transmits power between the connected shafts, ensuring smooth operation.

- Misalignment Management: While hubs provide a secure connection, flexible couplers can compensate for minor misalignments between the connected shafts.

- System Optimization: The combination of hubs and couplers allows for customization of power transmission systems, balancing factors like torsional stiffness, vibration dampening, and precision as needed.

- Maintenance Facilitation: The use of hubs and couplers can simplify machinery maintenance by allowing for easy disassembly and component replacement.

By working together, hubs and couplers create robust, efficient, and adaptable power transmission systems crucial for various industrial applications, from CNC machining to robotics